DESIGN

-

2D/3D CAD MODELING

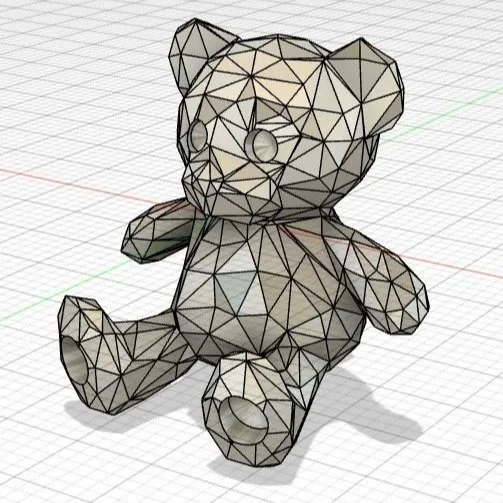

Using advanced 3d modelling software like SolidWorks and Fusion 360, we create detailed models for everything from prototypes to full production runs. Serving industries like healthcare, automotive, and consumer goods, our design process ensures accuracy, flexibility, and rapid turnaround times.

Stratalabs offers the ability to tailor your designs to precise requirements, effortlessly transforming concepts into practical applications via our additive manufacturing.

-

3D SCANNING

Stratalabs uses advanced 3D scanning technology to complement its 3D modelling services. High-precision scanners captures intricate details of physical objects to create organic accurate digital models.

This process enables reverse engineering, and the production of highly customized parts. Stratalabs expertise in 3D scanning ensures seamless integration with its 3D printing capabilities, precise and efficient solutions for clients.

-

TECHNICAL DRAWINGS

Professional technical drawing services designed to meet the highest industry standards. Our team specializes in creating precise, detailed 2D and 3D drawings tailored to your specifications, ensuring clear communication and accuracy throughout the design process.

Whether for additive manufacturing, or controlling manufacturing tolerances, Stratalabs delivers high-quality technical drawings that streamline workflows while reducing non-conforming parts.

-

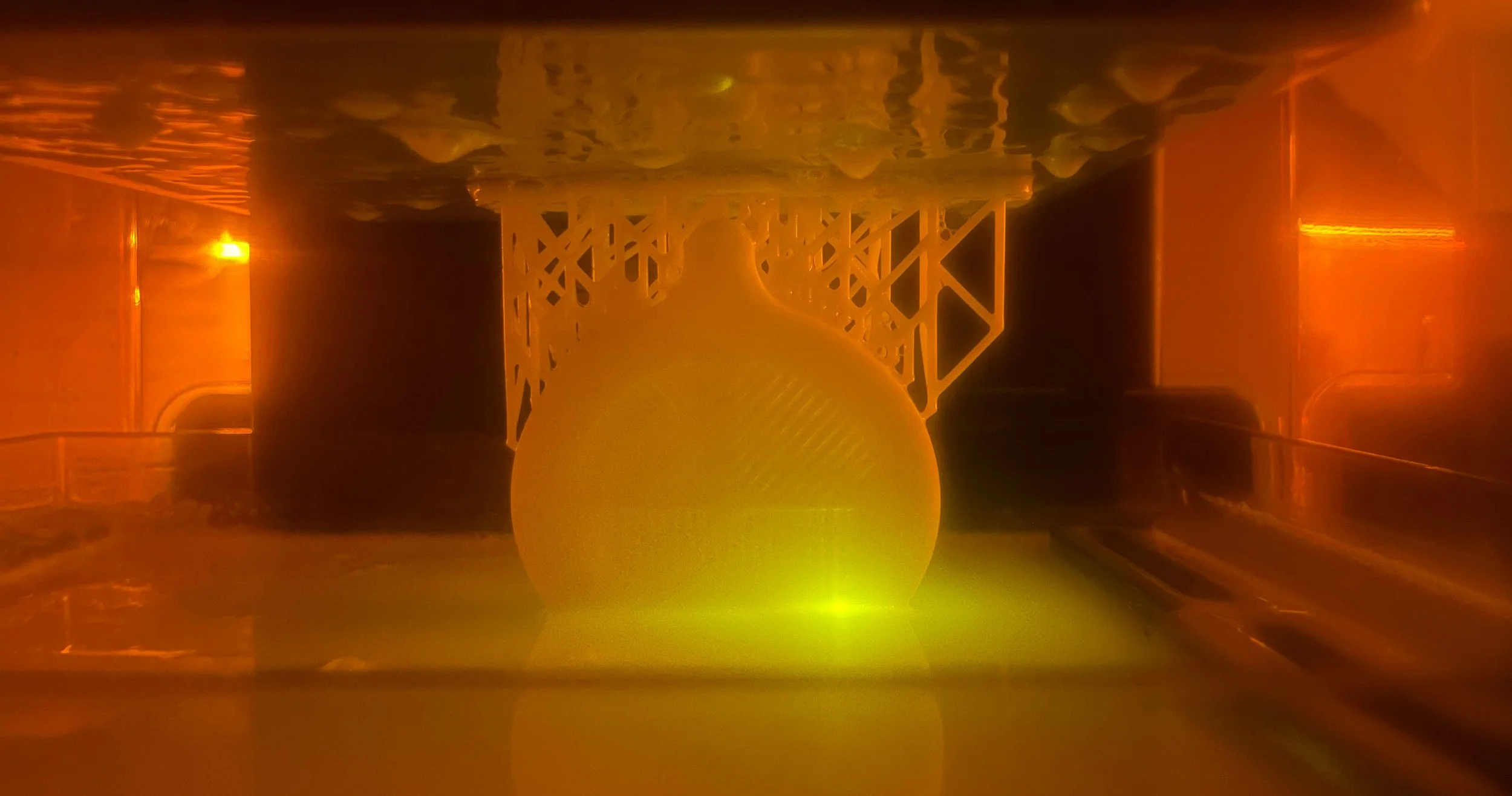

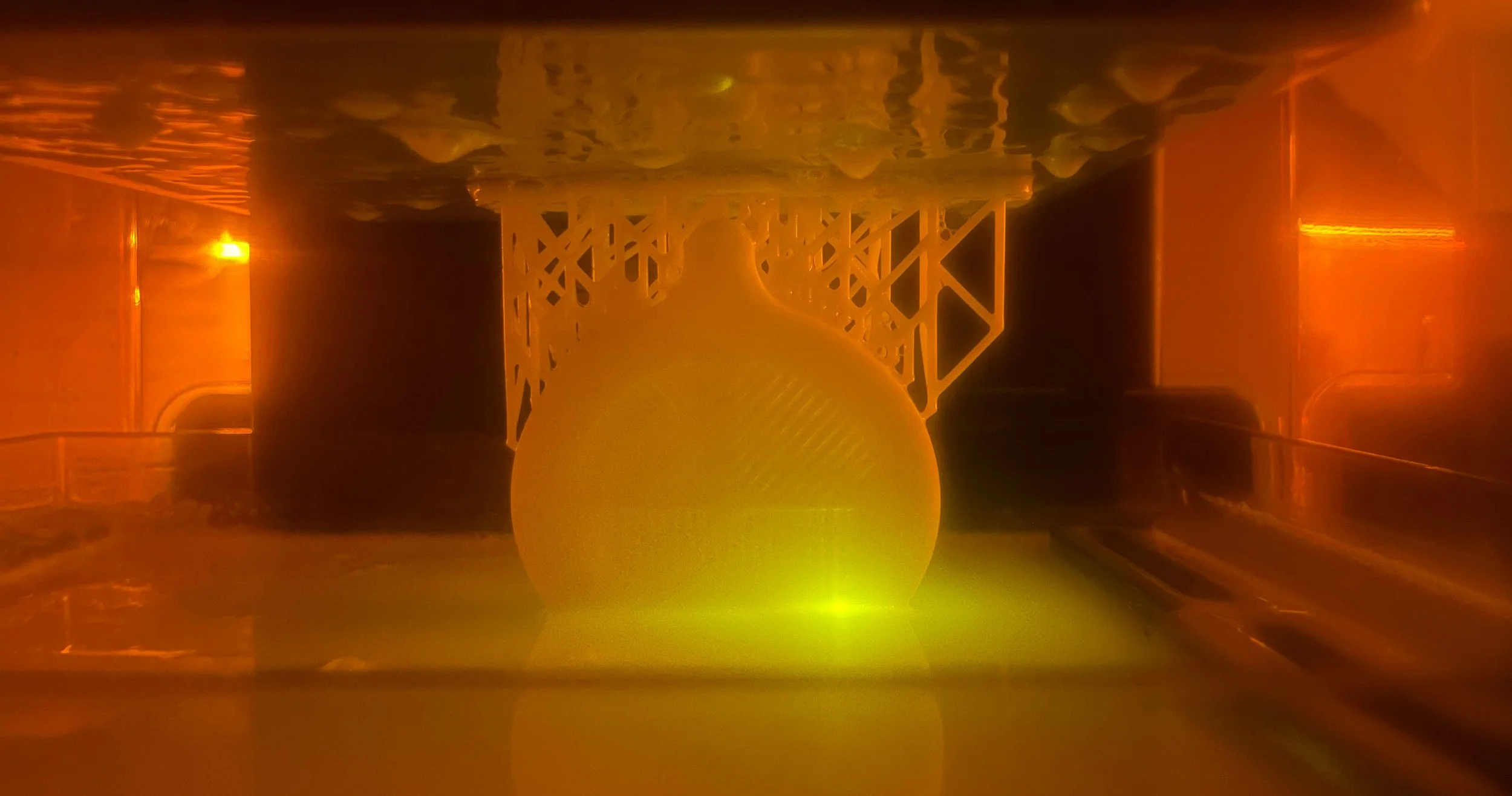

SLA PRINTING

SLA (Stereolithography) 3D printing offering precise and smooth surface finishes for even the most complex designs. Using advanced SLA technology, Stratalabs delivers exceptional accuracy and detail, making it ideal for prototypes, intricate models, and end-use parts.

Our expertise ensures fast turnaround times and materials tailored to your project’s requirements, including options for durability, flexibility, and heat resistance.

. -

DLP

Advanced DLP (Digital Light Processing) 3D printing, delivering exceptional speed and precision for detailed parts and prototypes. Unlike SLA (Stereolithography) printing, which uses a laser to cure resin point by point, DLP uses a digital light projector to cure an entire layer simultaneously, resulting in faster production times without compromising accuracy.

This makes DLP ideal for intricate designs in industries such as healthcare, jewellery, and engineering.

-

FDM

FDM (Fused Deposition Modelling) printing services, providing reliable and cost-effective solutions for prototypes, functional parts, and end-use products.

Our expertise includes a wide range of filament options, such as PLA/CF, ABS, PETG, NYLON/CF,TPU (flexible), carbon fibre-reinforced, and wood-filled materials, ensuring the versatility to meet various project requirements. Whether for rapid prototyping or low-volume production, Stratalabs is committed to delivering quality.

CAST

-

DIRECT BURN-OUT MATERIALS

3D printing with castable resin/filament, offering a precise and efficient solution for industries such as jewelry, dentistry, and aerospace. Castable resins/filament are designed to burn out cleanly during the casting process, ensuring flawless impressions with exceptional detail and smooth finishes.

This technology enables the creation of intricate designs with out the need for silicone molds and wax injection this reduces production time compared to traditional methods.

-

SILICONE/VULCANISED MOLDS

Molds are an integral part of investment casting its about choosing the right material for the project. While direct burn out materials are suitable for small production runs, molding is still the most cost effective way to fulfil large production runs,

Using vacuumed silicone or vulcanised rubber Stratalabs creates moulds capable of capturing the finest of detail and geometries, All our molds are optimised for wax injection this ensures exceptional accuracy, repeatability, and a smooth surface finish, reducing the need for extensive post-processing.

-

NON-FERROUS ALLOYS

Stratalabs specialises in lost wax casting using a variety of high-quality non-ferrous alloys, including aluminium, brass, bronze, and copper. These alloys are ideal for producing durable, lightweight, and corrosion-resistant components with intricate details and smooth finishes.

Non-ferrous alloys offer excellent versatility, making them suitable for applications in industries such as aerospace, automotive, jewellery, and art.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!